Lead Paint Removal Service-- NYC's Trusted Solutions for Lead Safety And Security

Essential Devices and Approaches for Reliable Lead Offense Cleaning

Resolving lead offenses successfully requires an extensive method that blends the right devices with strategic methodologies. The first step involves equipping employees with Individual Safety Devices (PPE) to secure their health and wellness. Simultaneously, making use of specialized clean-up devices, such as HEPA vacuum cleaners and lead-specific cleaning representatives, is critical for detailed pollutant removal. Efficient containment techniques, including plastic sheet and unfavorable atmospheric pressure systems, are necessary to prevent the spread of unsafe materials. Risk-free disposal practices and rigorous adherence to regulatory standards guarantee responsible handling of hazardous waste. What are the nuanced approaches that really make a distinction?

Individual Safety Devices

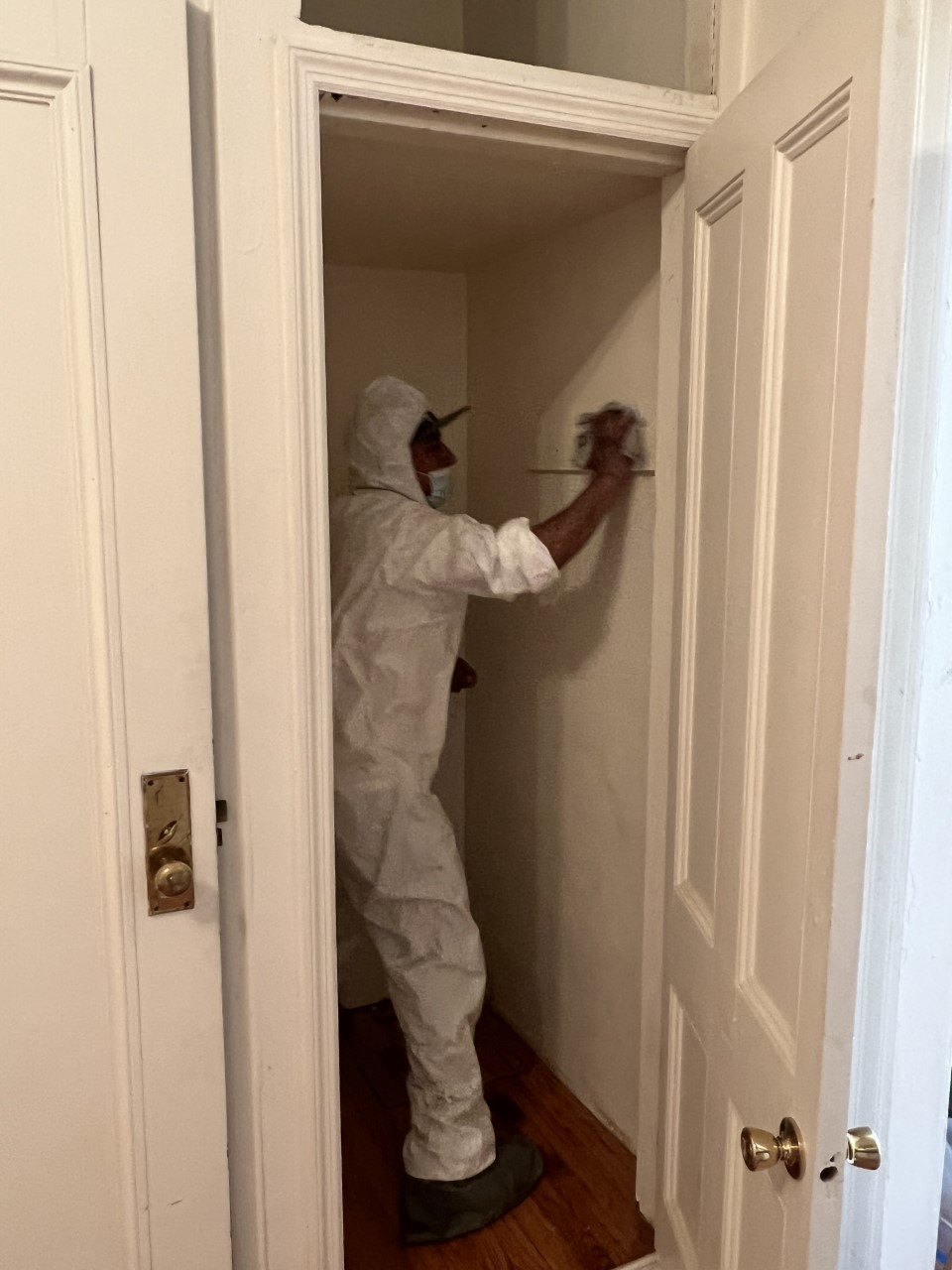

Individual safety tools (PPE) is a critical component in the efficient management of lead contamination clean-up. The vital PPE for lead clean-up consists of respirators, protective clothes, gloves, and eye security.

Respirators, especially those geared up with HEPA filters, are essential for filtering system air-borne lead bits, stopping inhalation. Protective garments, consisting of coveralls and disposable suits, protects against lead dust from sticking to employees' garments, lowering the risk of second contamination.

In addition, rigorous training on the proper use and upkeep of PPE is essential. Workers have to be informed on putting on and doffing procedures to prevent contamination. Routine examinations and replacements of PPE components are essential to maintain their protective capabilities, ensuring a safe and compliant cleaning operation.

Specialized Cleanup Equipment

One more important device is the wet/dry vacuum cleaner, which can efficiently tidy up both dirt and liquid contaminants. These vacuums often feature HEPA filters to supply an additional layer of security. Wet cleans or tack towels are also vital for surface area cleansing; they are particularly developed to catch and hold lead fragments, reducing the threat of spreading out contamination.

For even more persistent down payments, specialized lead-removal cleaning representatives are needed. These agents are developed to damage down lead particles, making them simpler to remove. Scrub brushes with durable bristles can assist in this process, especially on rough surfaces where lead dust tends to adhere more strongly.

Furthermore, encapsulants are used to secure lead-contaminated surfaces, protecting against the release of lead dirt. These specialized paints and coatings are created to abide by various substratums, giving a lasting remedy for lead containment.

Effective Containment Methods

Effective control techniques are vital in mitigating the spread Clicking Here of lead contamination throughout cleanup activities. Applying durable containment techniques makes certain that lead bits do not migrate to untouched areas, thereby shielding both workers and the setting (DOH & HPD Lead Violation Removal NYC).

To enhance containment, encapsulants can be used to surface areas that are not being eliminated or interrupted. These specialized finishings bind lead dirt, lowering its schedule for resuspension. Furthermore, all personnel have to put on ideal Individual Protective Equipment (PPE), consisting of respirators and disposable fits, check over here to stop contamination spread.

Safe Disposal Practices

Ensuring secure disposal methods is an essential component in the monitoring of lead contamination clean-up. Correct disposal minimizes the danger of lead re-entering the atmosphere and jeopardizing public health and wellness. The initial step is to determine and set apart lead-contaminated waste from other products. Safe and secure containment utilizing sturdy, leak-proof containers is crucial to prevent splilling throughout transportation.

Transporting lead waste requires adherence to stringent standards. Making use of licensed dangerous waste service providers ensures that the materials are dealt with properly. Paperwork, consisting of manifests outlining the kind and quantity of waste, need to go along with deliveries to track the waste from the site of origin to its last disposal destination.

Designated contaminated materials disposal facilities are outfitted to deal with lead-contaminated products safely. These centers commonly employ advanced approaches such as stabilization, solidification, or chemical therapy to reduce the effects of the lead before disposal. Landfilling in specialized, lined areas that avoid leachate from contaminating groundwater is a common practice for last disposal.

Normal training for employees associated with lead waste disposal my sources is important to maintain safety criteria and stop unexpected exposure. By adhering to these techniques, companies can significantly minimize the ecological and health and wellness effects associated with lead contamination.

Regulatory Conformity Tips

Complying with regulative compliance is vital in the successful implementation of lead contamination clean-up. Recognizing and adhering to federal, state, and local regulations makes sure not only the security and wellness of people however also the legal and financial wellness of the clean-up organization. The Environmental Security Firm (EPA) establishes rigorous requirements, such as the Lead Renovation, Repair Work, and Painting (RRP) Rule, which mandates appropriate accreditation and training for professionals managing lead-based activities.

Compliance starts with a comprehensive assessment of suitable laws and policies. Organizations needs to remain updated on any legal changes, which can be facilitated through routine training sessions and registering for industry updates. Documentation is one more essential conformity facet; preserving detailed records of all activities, consisting of inspection reports, staff member training logs, and disposal materializes, is crucial.

In addition, involving with accredited lead examiners or run the risk of assessors guarantees that lead hazards are correctly recognized and reduced. Companies have to implement using Individual Protective Equipment (PPE) and ensure that security protocols are strictly complied with. Last but not least, transparent communication with stakeholders, including workers, customers, and governing bodies, will promote a culture of conformity and liability, eventually contributing to a more secure and extra efficient lead cleanup procedure.

Final Thought

Effective lead violation clean-up necessitates the integration of specialized tools and critical methodologies to ensure security and effectiveness. Individual safety equipment (PPE) safeguards employees from direct exposure, while secure disposal techniques and strict adherence to governing conformity are crucial for responsibly managing unsafe waste.